Dow Jones Brake participated in the "2022 China Brake Annual Conference"

Stopart

On October 25-26, 2022, the "China Brake 2022 China Brake Annual Conference" hosted by ATC Automotive Technology Conference was successfully held in Hangzhou. The conference brought together excellent experts from vehicle manufacturers, brake assembly, frame, chassis system parts manufacturers T2, simulation&design, testing equipment and institutions, material manufacturers, scientific research institutions and colleges.

Led by Liu Ruqiang, General Manager of Shandong Daopuan Brake Materials Co., Ltd., Li Dengchao and other four people discussed the hot topics of carbon ceramic disc in the future brake system intelligence, key parts, lightweight, new materials, intelligent manufacturing and other automotive braking, which promoted the industry exchange and promoted the technical exchange and progress between automotive brake enterprises.

Grand scene

China Brake Annual Conference is the annual event of the brake industry with the longest history, the largest scale and the strongest technical influence in China, and has become one of the three major automobile brake technology conferences in the world. This summit subdivided the four sub-forums of passenger cars, commercial vehicles, brake linings, and brake raw materials, and discussed the hot topics related to automobile braking, such as the future intelligent braking system, key components, lightweight, and new materials.

Exhibition exchange

At this exhibition, the new process coated carbon ceramic brake disc products exhibited by Dopan have been widely recognized by the industry in terms of appearance and performance. Dopan has become the benchmark of the international long-fiber carbon ceramic brake disc, and jointly create a bright future for China's automobile modification industry.

At the exhibition, the Dupuan team carried out close exchanges and communication with experts in the industry on the application and optimization of carbon ceramic brake discs in the automotive modification industry, and won the favor of many customers with progressiveness technology and professional service.

Product introduction

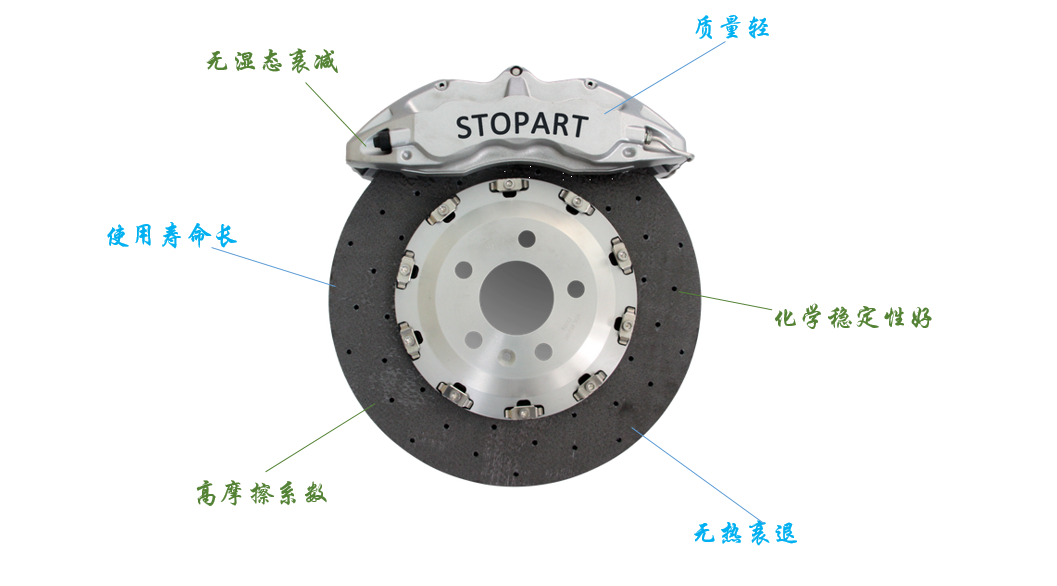

On the carbon ceramic brake disc, the hardness and surface smoothness of the carbon ceramic brake disc have been greatly improved by special material treatment on the surface of the traditional long-fiber carbon ceramic brake disc. The traditional single-pressure friction brake has been changed into friction+self-priming brake. The braking force and brake stability have been improved by more than 10%, and the service life has reached 800000 kilometers. It can maintain good braking under the high temperature of 1300 ℃, which is 20% - 30% shorter than the ordinary steel brake disc, It can also ensure the safety of emergency braking, and let people better experience the excitement of racing and driving comfort.

Shandong Daopuan Brake Material Co., Ltd. has realized the centralized control of multiple furnaces, completed the workshop automation, and effectively combined the application of the information system, becoming the first automatic production line of carbon ceramic disc machining in China.

Dupuan cooperates with many key universities at home and abroad, specializing in the research and development of friction products. The carbon/carbon and carbon/ceramic brake series products have obtained 27 patent achievements and undertaken 2 provincial scientific research projects. The product has excellent performance such as light weight, high strength, high temperature resistance and wear resistance, and has been successfully applied to the retrofit of Porsche, Maserati, Ferrari, BMW, Mercedes and other models.